Engineering Excellence: Building Tomorrow's Innovations Today.

Metal Solution

We at METSOLS are providing metal solutions by offering top quality “Metal Cutting Machine Tools” since 2010. Our Product range is covering all the machining process for production of engineering parts & components using different metals.

MET SOLS

20 Years Of Undefeated Success

In the dynamic landscape of modern manufacturing, a fervent dedication to metal cutting is essential for maintaining a competitive edge. We wholeheartedly share that dedication. Armed with a deep comprehension of the challenges your business faces, we furnish you with cutting-edge metal cutting tools and solutions aligned with the aspirations of your company. Together, we play a pivotal role in shaping the future of the manufacturing industry.

512+

Successfully Project Finished.

20+

Years of experience with proud

1120+

Revenue in 2017 investment

1520+

Colleagues & counting more daily

Our Products

Engineering Excellence

Varicut M42

Precision-engineered blades for superior cutting performance and durability.

Bi-Alfa Cobalt M42

Advanced cobalt alloy technology for enhanced cutting efficiency and extended tool life

Bi-Alfa Master Supreme

"Power Generation Industry: Harnessing energy to illuminate the world and drive progress."

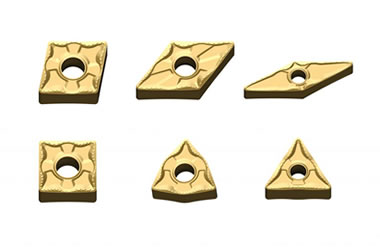

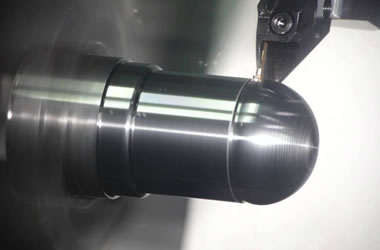

General Turning

Precision shaping of materials for diverse industrial applications with efficiency and accuracy.

Parting & Grooving

Precision machining solutions for clean cuts and intricate designs in manufacturing.

Indexable Milling

High-efficiency machining with versatile cutting inserts for increased productivity and precision.

CNC Machine Tools

Band Saw Blades

Offering Complete CNC Machining Solutions by our Partner

M/S ZCC-CT, to our customers engaged in manufacturing of engineering parts and components using different metals.

We are competent to provide machine tools for following Processes;-

- General Turning

- Parting & Grooving

- Threading

- Indexable Milling

- Solid Carbide End Mills

- Indexable Drilling

- Solid Carbide Drills

- Reamers

- Thread Cutters / Taps

- Boring System

Offering complete sawing solution using German Band Saw Blades by over Partner

M/S Robert Rontgen for cutting the variety of industrial metals. We always maintain good stocks for different types of Band Saw Blades as per customer’s cutting requirements.

Our “Band Saw Blade Welding” facility is fully equipped with latest welding machines and instruments as per German standard and technology.

We can assure to supply any size of “Welded” band saw blade on urgent orders.

- Varicut M42

- Bi-Alfa Cobalt M42

- Bi-Alfa RP Master

- Bi-Alfa Cobalt M51

- Bi-Alfa Master Supreme

- HM-Titan(Carbide Tipped)

Sustainability

Innovating Tomorrow: Engineering Excellence Today.

Sharper Tools, Brighter Tomorrow: Engineering Precision for Cutting-Edge Solutions

We Follow Best Practices

Driving Progress through Disciplined Innovation: Engineering Industry Best Practices.

- Sustainablility

- Project On Time

- Modern Technology

- Latest Designs

Tailored Metal Solutions for Engineering Triumphs.

Elevate your projects with our bespoke metal solutions, meticulously crafted for engineering excellence. From precision to performance, we redefine possibilities for the industries we serve.

Pioneering Metal Solutions, Engineering Success for Industries.

Request a Quote

Learn More From

Frequently Asked Questions

Machine cutting tools are precision instruments used in manufacturing and machining processes to remove material from a workpiece. These tools include drills, end mills, inserts, and other accessories, each designed for specific cutting tasks.

Machine cutting tools can be used to cut a wide range of materials, including metals (such as steel and aluminum), plastics, composites, and wood.

Selecting the right cutting tool involves considering factors such as material type, cutting speed, feed rate, and the specific machining operation. Consultation with tool manufacturers or experts can help in making an informed decision.

The lifespan of cutting tools depends on factors like material hardness, cutting conditions, and tool quality. Regular maintenance, proper tool storage, and adherence to recommended cutting parameters can extend tool life.

Optimize cutting tool performance by using the correct tool for the job, maintaining proper tool geometry, utilizing the right cutting fluids, and following recommended machining parameters provided by the tool manufacturer.